Metallo-supramolecular block copolymers

We are

synthesizing and characterizing a new type of amphiphilic block

copolymers, namely metallo-supramolecular amphiphilic block

copolymers. These compounds are formed by a hydrophilic

poly(ethylene oxide) A block linked to a hydrophobic B block such

as poly(styrene) through a

bis-2,2’:6’,2’’-terpyridine-ruthenium(II)

complex. The terpyridine ligand can easily be introduced at the

chain end of different polymers, thus giving rise to many possible

combinations of different blocks. Since the method for preparing

block copolymers relies on the coupling of two polymer chains via a

simple two-step synthesis using principles from coordination

chemistry around a ruthenium metal ion, it is straightforward to

prepare a library of block copolymers. Compared to

“classical” covalent block copolymers,

metallo-supramolecular block copolymers offer many advantages.

Besides the formation via self-organization processes, the

reversibility of the supramolecular bond allows the construction of

“smart materials” with tunable properties. Moreover,

the electrochemical and photochemical properties of the complexes

can be engineered by choosing the appropriate metal ion and

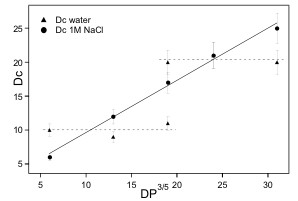

counter-ion. Recently, we focused on a library of

metallo-supramolecular block copolymers composed of poly(styrene)

and poly(ethylene oxide) joined by a bis-terpyridine-ruthenium

complex. The micelles formed from these copolymers have been

characterized by AFM and TEM. The results evidence that the

classical scaling laws relating the micelle size to the size of the

hydrophobic block are not valid for metallo-supramolecular

copolymers. This different behavior is due to electrostatic

repulsions between the charged and bulky metal-ligand complexes

present at the core-corona interface. If those repulsions are

screened by increasing the ionic strength during micelle formation,

the classical behavior is observed.

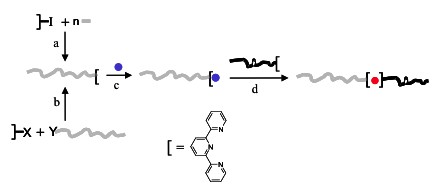

Schematic

representation of the synthetic strategy to prepare linear

metallo-supramolecular block copolymers. The first step is the

synthesis of the macroligands by either using a functionalized

(supramolecular) initiator (a), or grafting a terpyridine on a

reactive chain end (b). The second step is the preparation of a

mono-complex with RuIII (c).

Finally, the second block, bearing a free terpyridine unit, is

added to form a terpyridine-ruthenium(II) bis-complex

(d).

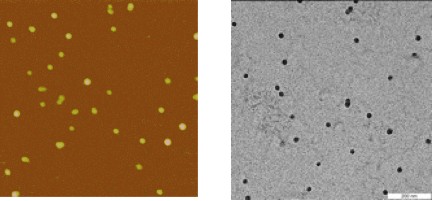

AFM

(left) and TEM (right) pictures recorded on micelles prepared from

the PS200-[Ru]-PEO375

copolymer in

water. AFM image is 11 µm.

Relationship

between the measured (AFM) core size of the micelles and the

3/5th power of the

PS block DP, for micelles prepared in pure water (triangles) and in

1M NaCl (circles). The solid line represents the linear regression

obtained from the data in 1M NaCl.

Researchers

involved: Pierre Guillet, Clément Mugemana

Collaborations:

Ulrich Schubert

(Eindhoven)

Relevant

papers:

"Study of the influence of the metal-ligand complex on the size of

aqueous metallo-supramolecular micelles"

P. Guillet, C.-A. Fustin, B. G. G. Lohmeijer, U. S. Schubert, J.-F.

Gohy

Macromolecules

2006, 39,

5484-5488

“Metallo-supramolecular block copolymers”

P. Guillet, C.-A. Fustin, U. S. Schubert, J.-F.

Gohy

Adv.

Mater.

2007, 19, 1665-1673