| Image |

Product |

Description |

|

|

3D printer CreatBot F430

Polymer processing

|

plus petit que p>3D printer equipped with dual extruders.plus petit que /p>

plus petit que p>Able to print High performance material like PEEK, PEI, etc (Tmax =420°C).plus petit que /p> |

|

3D printer Flashforge Creator 3

Polymer processing

|

plus petit que p>3D printer equipped with camera and 2 independent extruders.plus petit que /p>

plus petit que p>Support carbon fiber Filamentplus petit que /p>

plus petit que p>Maximum Set Temp. of Extruder: 300 ℃plus petit que /p> |

|

3D printer Makerbot-1

Polymer processing

|

plus petit que p>3D printer with dual extrusion that is optimized for printing with conventional thermoplastic filaments. plus petit que /p> |

|

3D printer Makerbot-2

Polymer processing

|

3D printer with dual extrusion that is optimized for printing with conventional thermoplastic filaments. |

|

DSM extruder/compounder

Polymer processing

|

plus petit que div>plus petit que span>plus petit que span>Labplus petit que /span>plus petit que /span> plus petit que span>plus petit que span>benchplus petit que /span>plus petit que /span> plus petit que span>plus petit que span>twinplus petit que /span>plus petit que /span> plus petit que span>plus petit que span>screwplus petit que /span>plus petit que /span> plus petit que span>plus petit que span>extruder/compounderplus petit que /span>plus petit que /span> plus petit que span>plus petit que span>withplus petit que /span>plus petit que /span>plus petit que span>plus petit que span> recycled loop.

plus petit que em>Specifications:

plus petit que /em>plus petit que /span>plus petit que /span>plus petit que span>plus petit que span>Maxplus petit que /span>plus petit que /span> plus petit que span>plus petit que span>sampleplus petit que /span>plus petit que /span> plus petit que span>plus petit que span>materialplus petit que /span>plus petit que /span>plus petit que span>plus petit que span> usage :15g

plus petit que /span>plus petit que /span>plus petit que span>plus petit que span>Max. plus petit que /span>plus petit que /span>plus petit que span>plus petit que span>screwplus petit que /span>plus petit que /span>plus petit que span>plus petit que span> speed 150 plus petit que /span>plus petit que /span>plus petit que span>plus petit que span>rpmplus petit que /span>plus petit que /span>plus petit que span>plus petit que span>;plus petit que /span>plus petit que /span>plus petit que span>plus petit que span>

Max. plus petit que /span>plus petit que /span>plus petit que span>plus petit que span>Temperatureplus petit que /span>plus petit que /span>plus petit que span>plus petit que span> 400°C

plus petit que /span>plus petit que /span>plus petit que span>plus petit que span>Accessories:plus petit que /span>plus petit que /span>plus petit que span>plus petit que span>pelletizerplus petit que /span>plus petit que /span>plus petit que span>plus petit que span>, injection plus petit que /span>plus petit que /span>plus petit que span>plus petit que span>moldingplus petit que /span>plus petit que /span>plus petit que span>plus petit que span> system and filament and film spooler.plus petit que /span>plus petit que /span>plus petit que /div> |

|

Extruder Process 11

Polymer processing

|

plus petit que span>Process 11 Parallel Twin-Screw Extruder.

plus petit que span>

plus petit que p>Lab bench twin screw extruders with the option of water assisted extrusion (Minimized sample material usage (20g); Throughput range 20g/h to 2.5kg/h; Max. screw speed 1000 rpm; Barrel Length L/D: 40 L/D; Max. Temperature 450°C).plus petit que /p>

plus petit que p>With accessories such as pelletizer and filament and film spooler.plus petit que /p>

plus petit que p>Available also a Thermo Scientific™ HAAKE™ MiniJet Pro Injection Molding for manufacturing tensile specimens according to ISO 527-1.plus petit que /p>

plus petit que /span>plus petit que /span> |

|

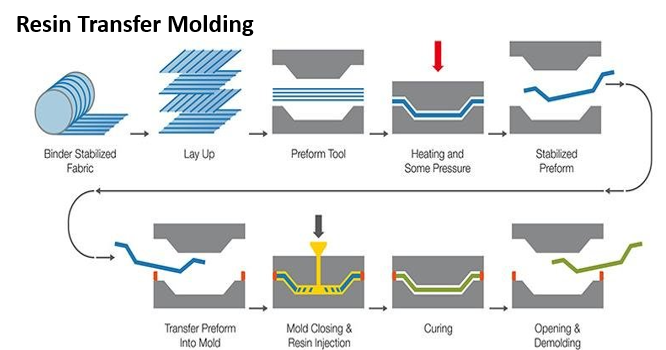

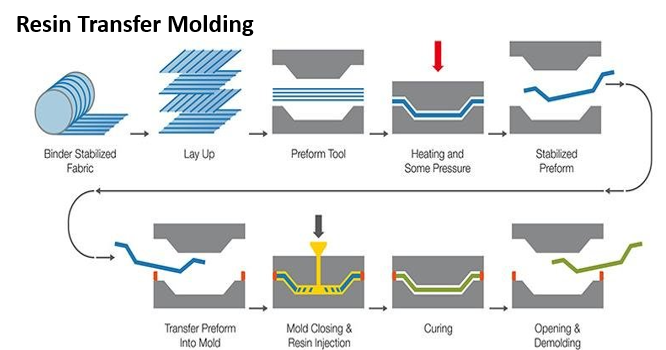

RTM/SQRTM

Polymer processing

|

Resin transfer molding (RTM) is a process for manufacturing parts in composite materials (polymer matrix/fibre reinforcement). It is an industrial process for injecting liquid resin at low pressure into a rigid and closed mould.

plus petit que span>What sets SQRTM (plus petit que span>Same Qualified Resin Transfer Molding) plus petit que /span>apart from standard RTM is that, in place of a dry fiber preform, it substitutes a prepreg layup. Prepreg plies are arranged within the mold, the mold is closed, and then, somewhat counterintuitively, liquid resin is injected into the tool

plus petit que p>plus petit que em>Specifications:plus petit que /em>plus petit que /p>

plus petit que p>Injector: 6Lplus petit que /p>

plus petit que p>Max pressure: 7barplus petit que /p>

plus petit que p>Max temperature : 180°Cplus petit que /p>

plus petit que /span> |

|

|

Anton Paar MCR 302e

Rheology

|

plus petit que p>This rheometer is a stress controlled rheometers equipped for melts, gels, etc. A wide range of measurement geometries and sample environments are present.plus petit que /p>

plus petit que p>Specificationsplus petit que /p>

plus petit que p>Min torque : 0,5 nNmplus petit que /p>

plus petit que p>Max torque : 230mNmplus petit que /p>

plus petit que p>Frequency range : 10-7rad/s- 100Hzplus petit que /p>

plus petit que p>Temperature measuring range : -50°C….+220°Cplus petit que /p> |

|

Anton Paar MCR 702e

Rheology

|

plus petit que p>This rheometer is a stress controlled rheometers equipped for melts, gels, etc. A wide range of measurement geometries and sample environments are present.plus petit que /p>

plus petit que p>Specificationsplus petit que /p>

plus petit que p>Min torque : 0,5 nNmplus petit que /p>

plus petit que p>Max torque : 230 mNmplus petit que /p>

plus petit que p>Frequency range : 10-7rad/s- 100Hzplus petit que /p>

plus petit que p>Temperature measuring range : -150°C….+450°Cplus petit que /p> |

|

ARES-1

Rheology

|

plus petit que p>The ARES rheometer allows the measurements of common rheological properties: visco-elasticity, viscosity, yield stress, … True strain controlled unit adapted for melts, solutions and suspensions.plus petit que /p>

plus petit que p>Can be operated in steady or dynamic modes.plus petit que /p>

plus petit que p>Linear and nonlinear shear tests.plus petit que /p>

plus petit que p>A wide range of measurement geometries are available. Temperature measuring range : -150°C to 600°Cplus petit que /p> |

|

ARES-2

Rheology

|

plus petit que p>The ARES rheometer allows the measurements of common rheological properties: visco-elasticity, viscosity, yield stress, … True strain controlled unit adapted for melts, solutions and suspensions.plus petit que /p>

plus petit que p>Can be operated in steady or dynamic modes.plus petit que /p>

plus petit que p>Linear and nonlinear shear tests.plus petit que /p>

plus petit que p>A wide range of measurement geometries are available. Temperature measuring range : -150°C to 600°Cplus petit que /p> |

|

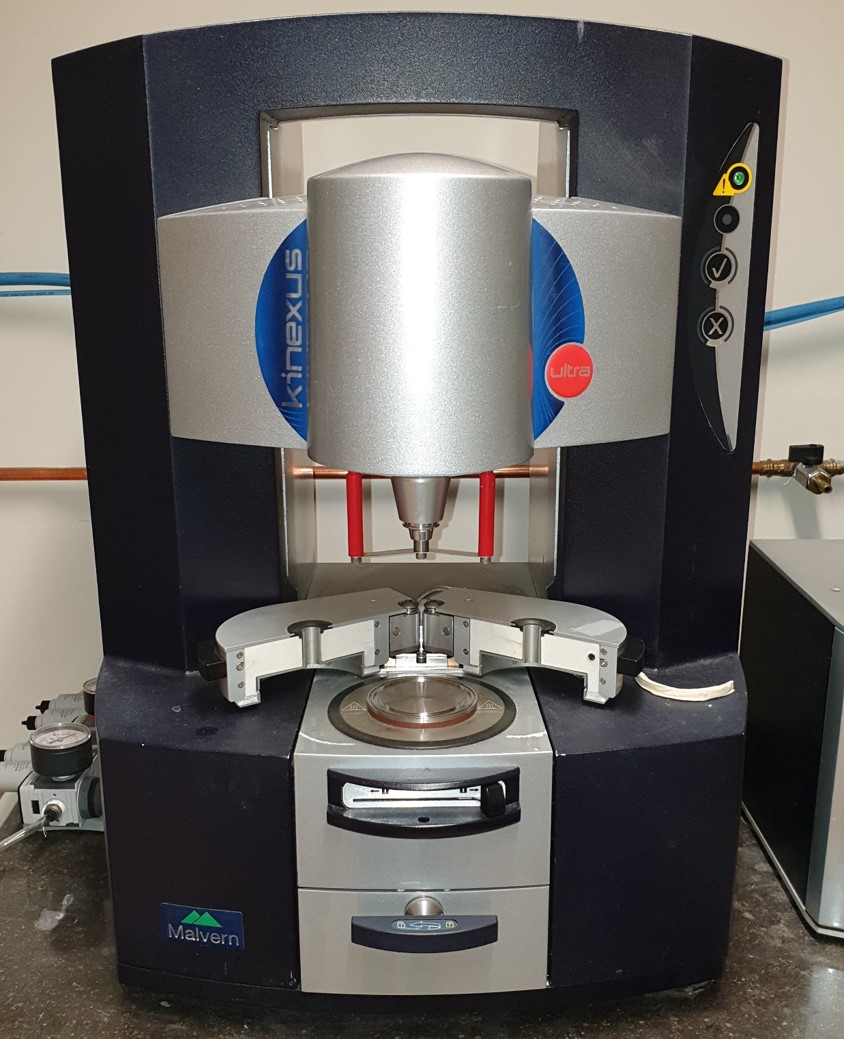

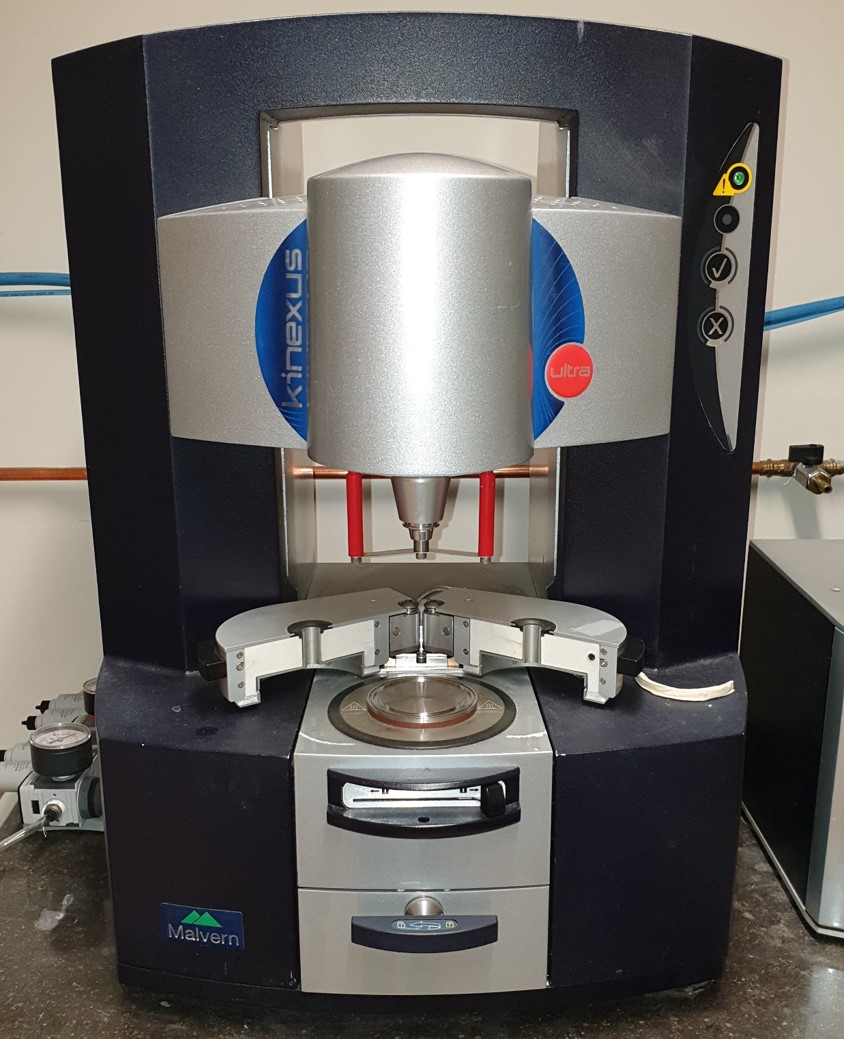

Kinexus

Rheology

|

plus petit que p>Specificationsplus petit que /p>

- Rotational (shear) control: torque, speed and position

- Vertical (axial) control: gap and normal force

- Temperature control (isothermal, ramp or table)

- Pelletier with a solvent trap

|

|

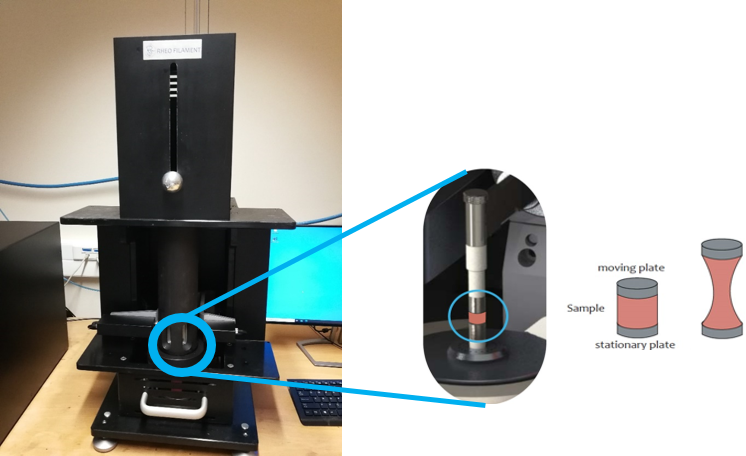

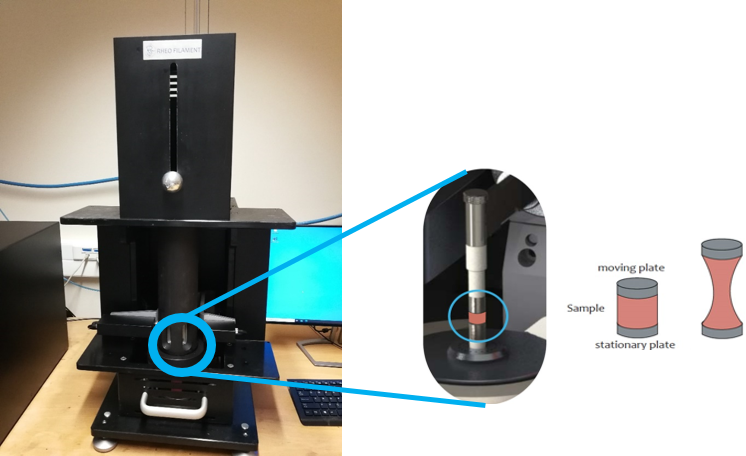

Vader 1000

Rheology

|

plus petit que p>Measurement of the rheological properties (viscosity, modulus, relaxation times) under uniaxial extension.plus petit que /p>

plus petit que p>Adapted for polymer melts.plus petit que /p>

plus petit que p>Temperature control.plus petit que /p> |

|

|

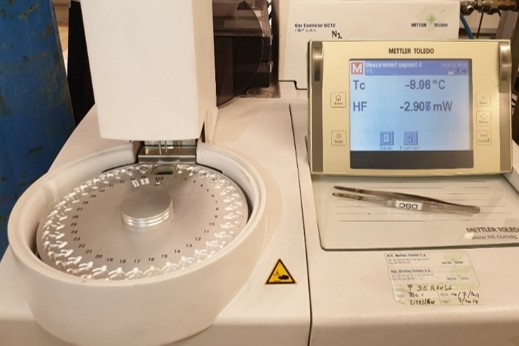

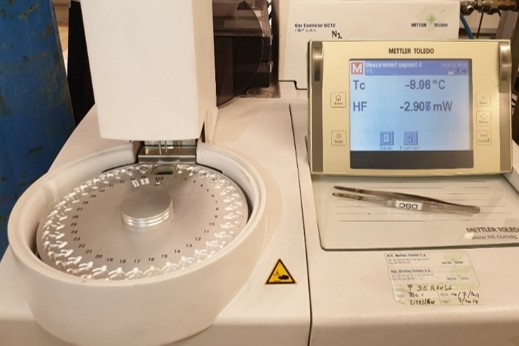

DSC 1

Thermal analysis

|

Differential Scanning Calorimetry (DSC) provides the determination of thermal transitions (glass transition temperature, melting, crystallization, etc.) and their associated energies.

plus petit que em>Specifications:plus petit que /em>

Temperature range: -90 to +500°C

Atmosphere: N2 or O2

Autosampler

Modulated DSC

TOPEM |

|

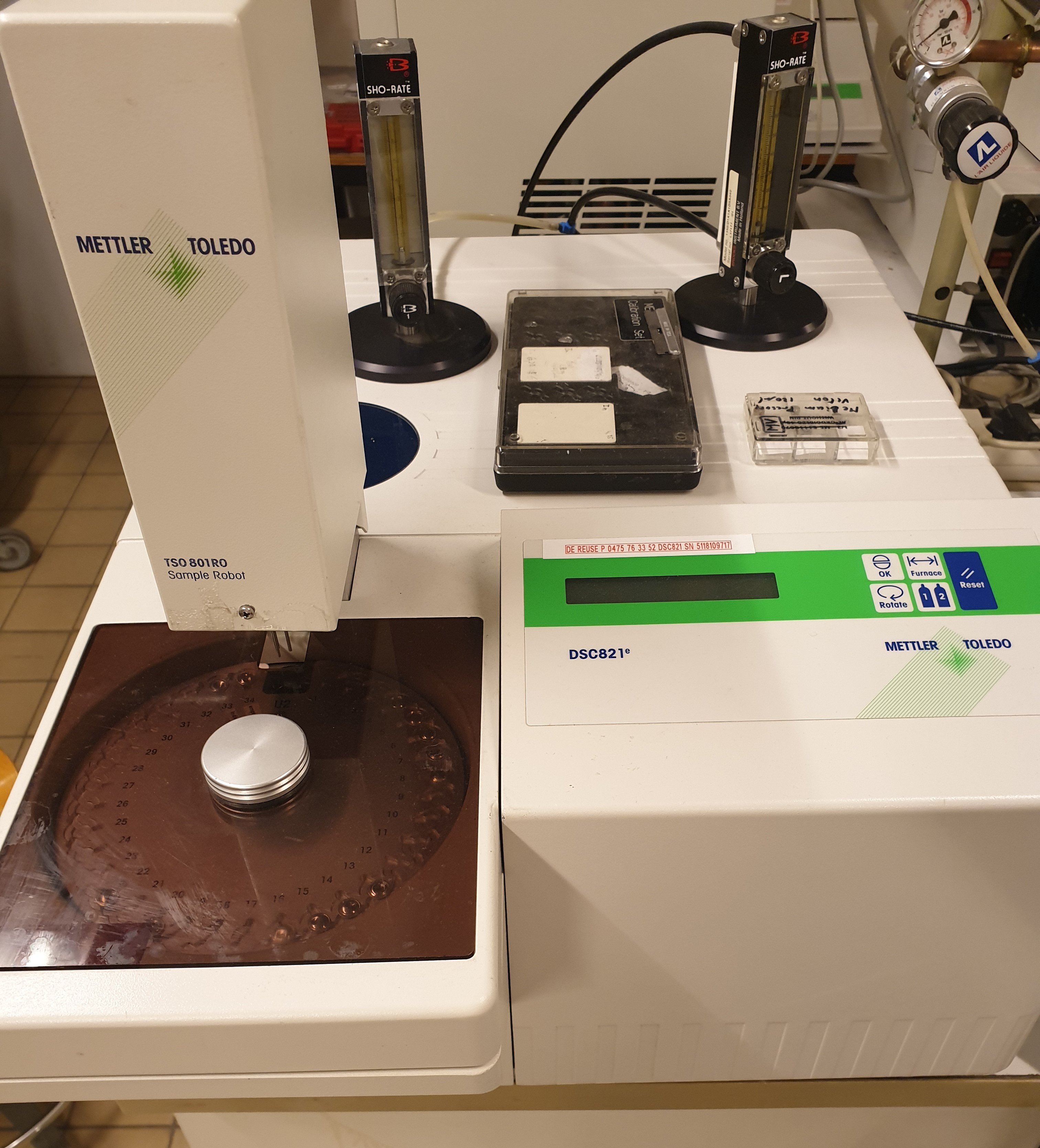

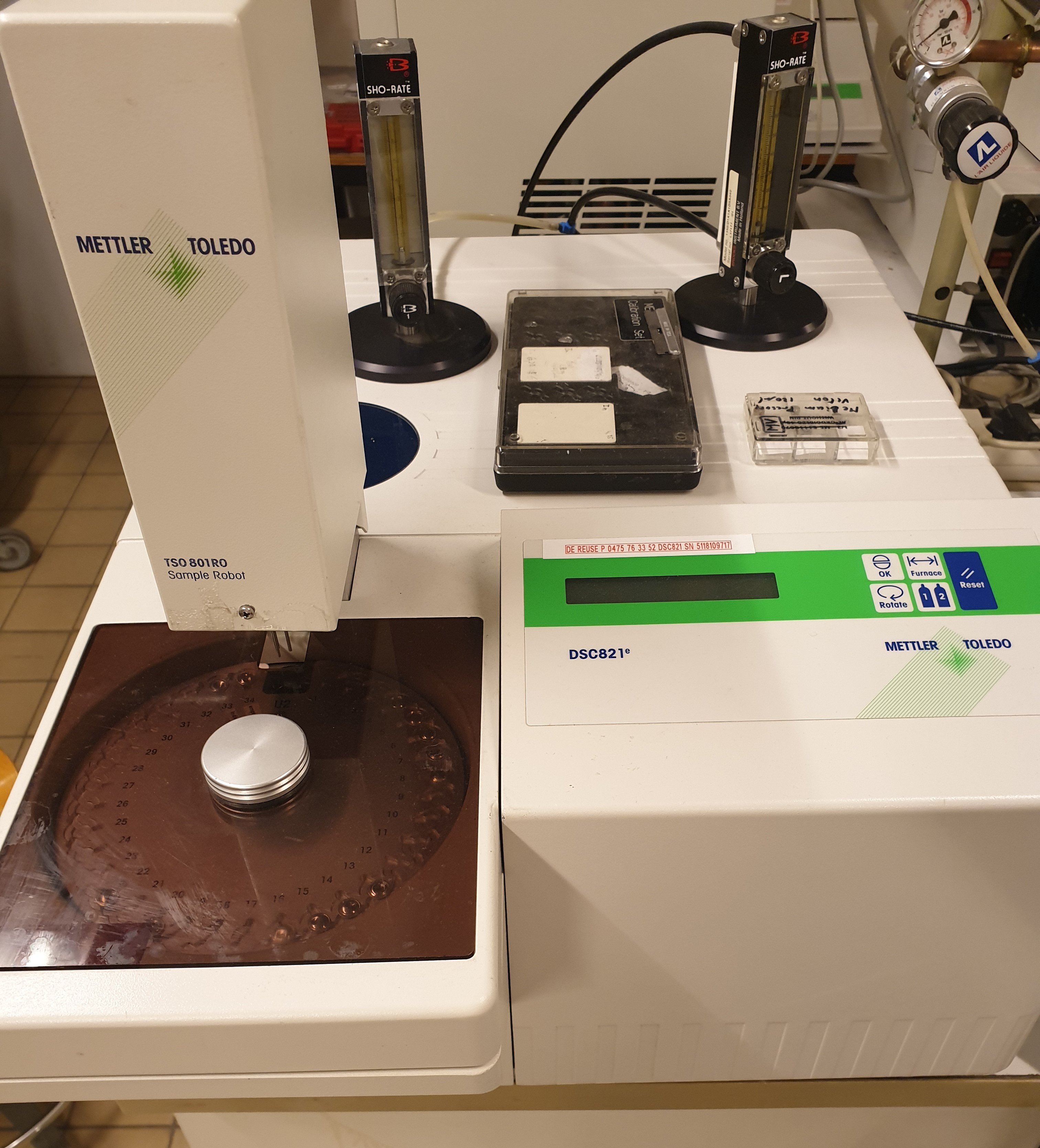

DSC 821

Thermal analysis

|

Differential Scanning Calorimetry (DSC) provides the determination of thermal transitions (glass transition temperature, melting, crystallization, etc.) and their associated energies.

plus petit que em>Specifications:plus petit que /em>

Temperature range: 25 to +700°C

Atmosphere: N2 or O2

Autosampler

|

|

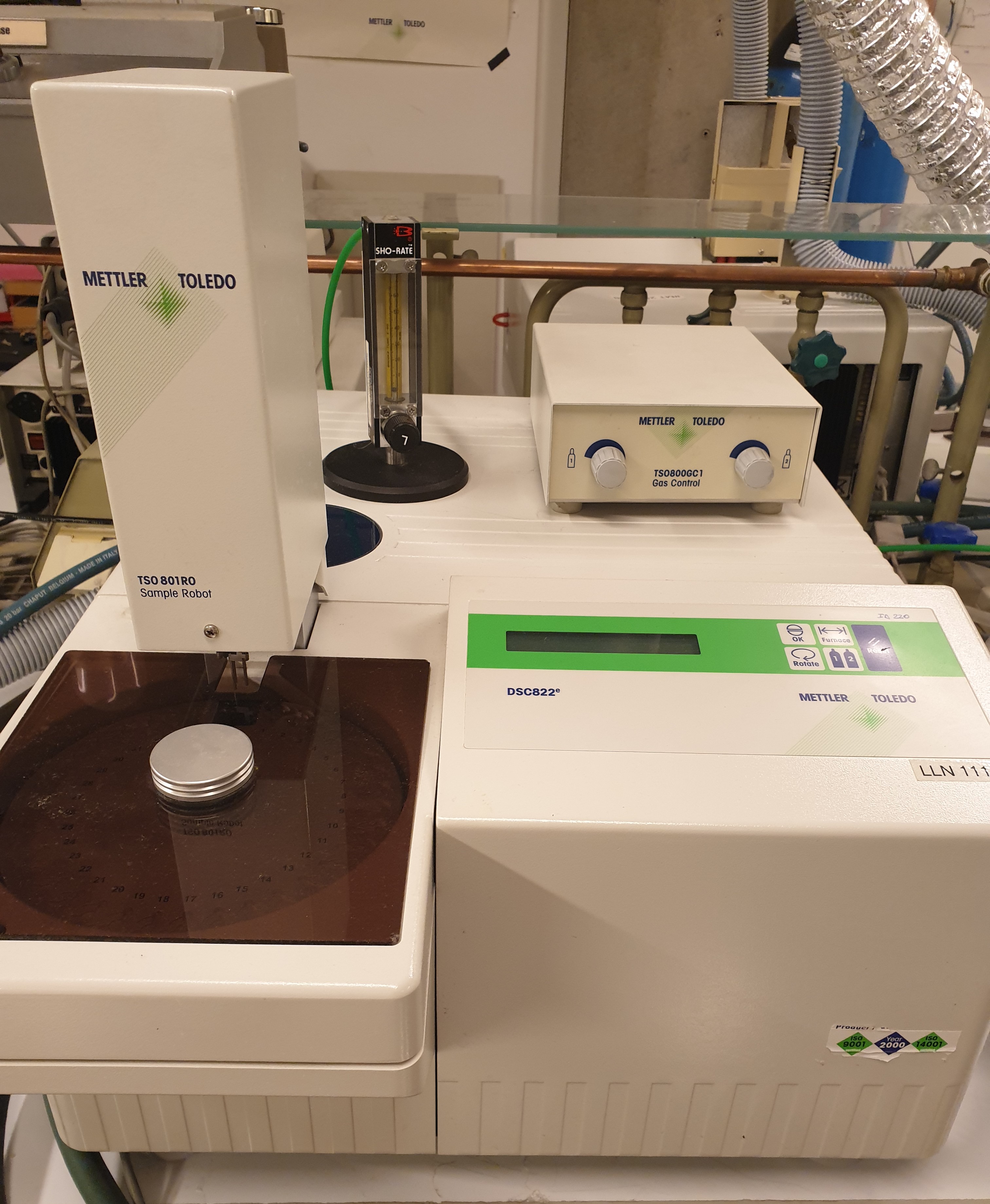

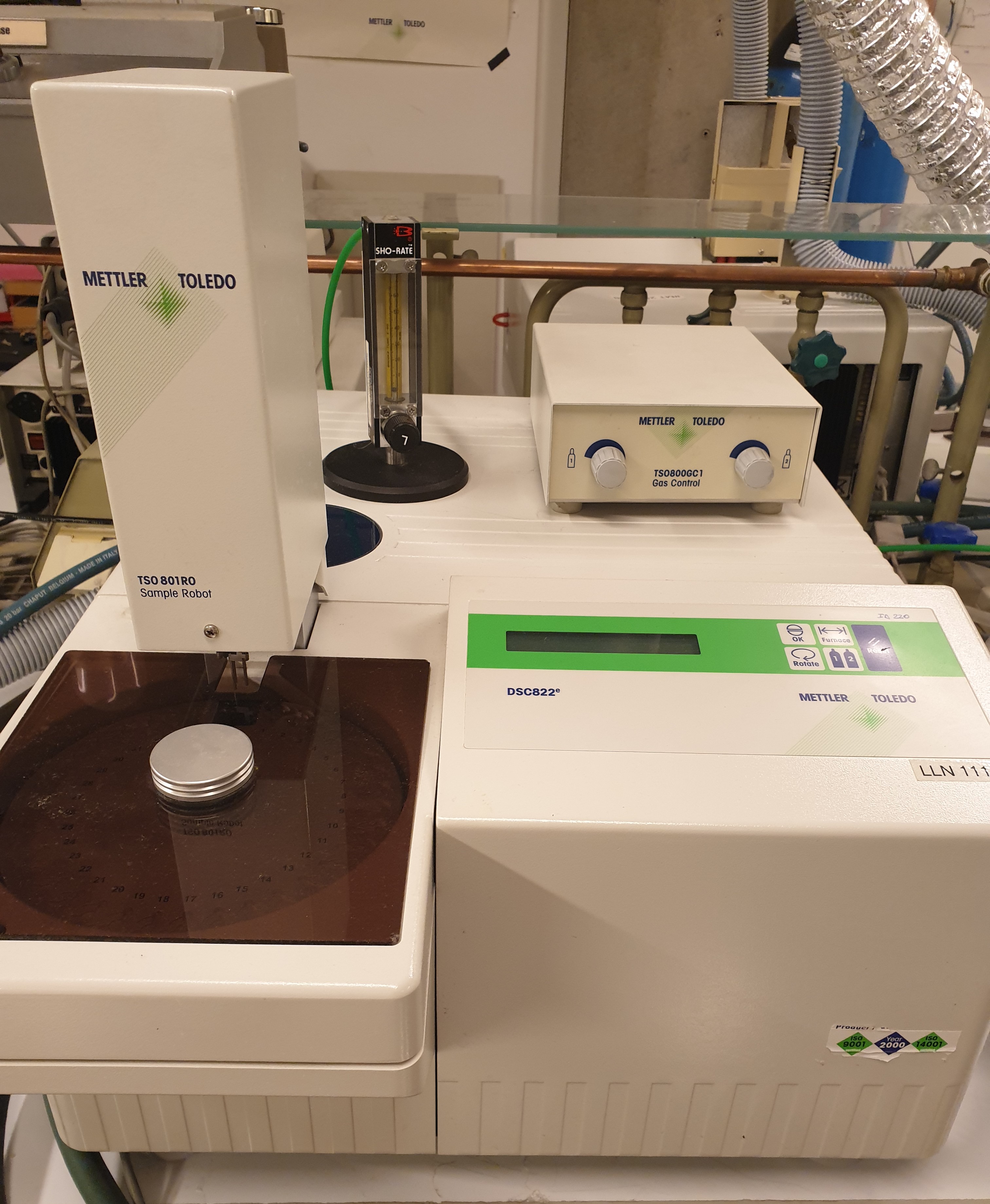

DSC 822

Thermal analysis

|

Differential Scanning Calorimetry (DSC) provides the determination of thermal transitions (glass transition temperature, melting, crystallization, etc.) and their associated energies.

plus petit que em>Specifications:plus petit que /em>

Temperature range: -150 to +700°C

Atmosphere: N2 or O2

Autosampler |

|

FDSC

Thermal analysis

|

With ultra-fast cooling and heating rates (a range range of more than 7 decades) of this differential calorimetric analyzer, it is possible to study chemical processes and thermally induced physical transitions, such as the crystallization and reorganization of polymers.

plus petit que p>Specifications:plus petit que /p>

plus petit que p>Cooling rate: -4000K/splus petit que /p>

plus petit que p>Heating rate: 40000K/splus petit que /p> |

|

HPDSC

Thermal analysis

|

plus petit que p>HPDSC 827 can be used to study the influence of pressure on thermal transitions (glass transition temperature, melting, crystallization, chemical reaction, etc.) of a sample.plus petit que /p>

plus petit que p>Max pressure: 100bar

Temperature range: +30 to +450°Cplus petit que /p> |

|

TGA

Thermal analysis

|

plus petit que p>TGA provides the study of the thermal stability of a sample as a function of time and temperature. Determination of residual water or volatile content, loading rate, etc.plus petit que /p>

plus petit que p>Autosamplerplus petit que /p>

plus petit que p>Temperature range : +30 to +1000°Cplus petit que /p>

plus petit que p>Atmosphere : N2 ou Airplus petit que /p> |

|

|

DMA

Thermomechanical analysis

|

Dynamic Mechanical Analysis (DMA) is a technique in which the elastic and viscous response of a sample under oscillating load, are monitored against temperature, time or frequency.

plus petit que p>plus petit que em>Specifications:plus petit que /em>plus petit que /p>

plus petit que p>Temperature range: -150 to +350°Cplus petit que /p>

plus petit que p>Deformation modes: compression, shear, tensile, bendingplus petit que /p> |

|

INSTRON Tensile Machine

Thermomechanical analysis

|

plus petit que p>Tensile machine equipped with 2 force cells, 100N and 10kN.plus petit que /p>

plus petit que p>Measurement of tensile mechanical properties between -100°C and +350°C.plus petit que /p>

plus petit que p>Optical extensometer allowing to measure the deformations without contact with the sample. Analysis of strain fields during measurement.plus petit que /p> |

|

TMA

Thermomechanical analysis

|

Thermo-mechanical analysis provides the determination of variations in the dimensions of a sample as a function of temperature (coefficient of expansion, glass transition, creep, softening point, etc.).

plus petit que em>Specifications

plus petit que /em>

plus petit que p>Temperature range : -150 to +350°Cplus petit que /p>

plus petit que p>DLTMAplus petit que /p>

plus petit que p>Frequency : -0,1…1,0Nplus petit que /p> |